The Western Glass Manufacturing Company

by Tom Katonak

Reprinted from "Crown Jewels of the Wire", June 2001, page 28

Background:

For many years, I've been a collector of Denver glass insulators

with a concentration on those produced by the Western Glass Manufacturing

Company. I recall the first purple insulator I ever owned - a WGM toll that I

bought at the Colorado Springs flea market back in 1985. I could hardly bear to

pay the negotiated price of three dollars, but the piece was gorgeous and I had

to have it! Ever since that time, my interest in the Denver glass has continued

to grow. The purpose of this article is to focus on the Western Glass

Manufacturing Company and provide information for collectors and historians

alike on one of the early and most important producers of glass insulators in

the west. The interesting story of the turn-of-the-century insulator production,

and the men who made the glass document a fascinating chapter in the history of

the industry.

History:

Glass production started in Valverde, Colorado, a small village just

southwest of Denver, about 1887. Bottles became the mainstay of the operation

early on. The plan called for making window and plate glass as well, but

bottles were in such high demand that they never got into the sheet glass

business. In 1895, famous glassmaker, Robert Good Jr., arrived on scene to take

up the glass business he had learned from his father in England and New York.

Good rented the glass factory at Valverde and a year later, the R. Good

operation was in full production with both insulators and bottles. Soon

thereafter, William McLaughlin (of later California fame) came to work at the

plant.

Disaster struck in the summer of 1899 when fire caused by a ruptured

glass tank destroyed most of the plant. The plant was rebuilt late in '99, but

the high cost of investment money precipitated a reorganization of the company

as the "Western Flint Glass Company". WFG was prolific in its

production of insulators as well as bottles. These items were shipped and used

throughout the Rocky Mountain west.

In late 1900, the glass works was

reorganized for the third and final time, this time as the "Western Glass

Manufacturing Company". WGM was even more prolific than its forerunners, and a major factory expansion

phase took place in 1904, more than doubling the available floor space. This

expansion is well documented on the Sanborn maps of the period. Again, the major

product was bottles, but the fast-growing telephone business gave them a huge

market for insulators, particular the toll type, as well. WGM remained in

operation until about mid-1909 when it could no longer compete with the new

bottle forming machines used by most of the newer glass works. Declining profits

during the last several years led the owners to cease operations. Apparently,

the seven principals in the company were unwilling to make the necessary capital

investment to modernize the plant in order to update the equipment to industry

standards.

Notwithstanding their ever-increasing financial difficulties, WGM

produced a major portion of the food, beer, wine, medicine, soda and water

bottles used in Colorado and surrounding states. During its nine years of

operation, it also produced the lion's share of the telephone insulators for

both industry and long-line communications in the Rocky Mountain States. Even

today, one still finds an occasional purple WGM toll on an isolated pole or

perhaps half buried in the shifting sand in the back country of Colorado or New

Mexico.

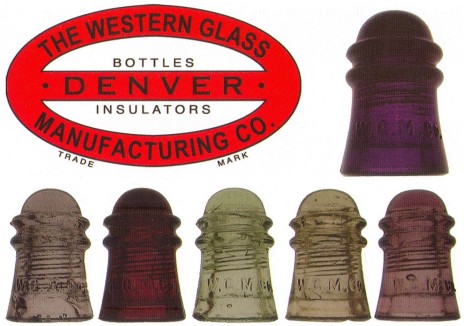

A fascinating side-bar to the history of WGM is that very little

documentation and virtually no records from the business operations have been

found to date. In fact, only two company letters with the original WGM

letterhead have ever been found and these documents are located in the

collections of the Colorado Historical Society in Denver. Thanks to these

letters, we know the precise shape of the WGM logo, which I have redrawn for

this article. The letterheads on record are black and white, so I've used some

"authors license" in making the color red. Nevertheless, it is quite

remarkable that for a major operation that produced and shipped thousands of

tons of glass products all over the west for nearly a decade, so little

documentation of the details survives!

Glass Production:

The R. Good operation produced primarily aqua colored

insulators in CD's 106, 121, 134, and 162, although a brightly colored toll

turns up occasionally. When WFG assumed control in 1899, less care was taken in

the manufacturing process, and many insulators were produced that "wouldn't

have met the specification" if Robert Good were still in charge! Many WFG

"slumpers", "leaners", "steamers" and other crude

pieces have been found over the years and in some quite handsome colors.

When

WGM started up their operation, they used new molds and new glass mixtures for

their insulators. Their glass tended to be much more consistent in form and the

colors more uniform. In addition, they added the beehive (CDI45) to their style list due to the demand-pull from railroad

telegraphy. There are some that think the WGM insulators are "boring"

most being some shade of purple due to the addition of manganese dioxide.

However, there are many shades and hues of purple and other beautiful colors as

well: peach, ginger ale, silver, burgundy, gold and light green examples are

known - and photographs of many of these accompany this article.

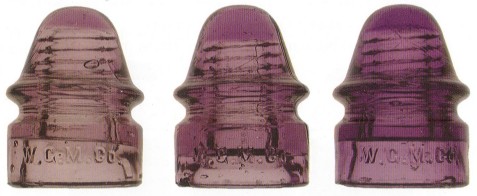

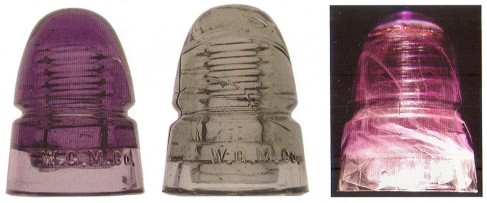

Let's consider

the purple insulators for a moment: As it turns out, the lighter the shade of

purple glass, the more uncommon the piece. Deep purple WGM insulators are

perhaps two or three times more plentiful than the lighter purples.

Interestingly, the prices for the various shades of purple insulators do not

reflect the scarcity in that the deep or royal purples often command the higher

value. This, no doubt, reflects the "desirability factor" as opposed

to an evaluation based on scarcity alone. Another interesting aspect about the

purple glass is that there are two basic shades of the color: There is the more

common "red-purple" subgroup and the less frequently occurring

"lavender-purple" subgroup. This distinction becomes immediately

apparent when putting a random grouping of 50 tolls in a sunny window or

light-box and inspect the color variations in detail.

Looking at the variety of

the five WGM CD's, we note that the shapes of all the pieces are remarkably

different than the earlier Denver production. Particularly noteworthy is the CD

106 that has a "contemporary look" for that style of insulator. In

fact, most collectors agree that the WGM CD 106 is the prettiest of all the CD

106s. Also noteworthy is the fact that there are two major mold styles for the

CD 145 - "chunky" and "narrow". The narrow style is similar

to the postal beehive shape. No production records of the various insulator

types have ever been found, but based on the "findability" of WGMs

today, one would surmise that the tolls were the style of greatest production.

CD 145s are fairly common too, but they are far fewer in number than the tolls.

The third most common piece appears to be the CD 162 signal, followed by the CD

106 ponies. The least common of the suite is the CD 134s, making up perhaps only

one or two percent of the pieces found.

In an exciting recent development,

research currently being carried out by Mike Miller (of Denver) on the

production of both the embossed and un-embossed AM TEL & TEL toll insulators

is showing that there is a high probability that some of these may have been

manufactured by WGM circa 1909!

The Insulators:

The photos accompanying this article depict all five of the

WGM styles and attempt to demonstrate the range of color found in these

varieties as well.

Consider first the CD 106 ponies. As I mentioned earlier, the ponies are not

as abundant as some of the other CD's and their "swoop skirt" styling

is unique among the CD 106 variants. The ponies do not seem to occur in the deep

royal purple shades that the tolls and beehives are commonly found in and are

most usually located in a pleasing medium purple shade. Only occasionally will

you locate a royal purple or "black purple" specimen. The photo

grouping of ponies shows the range of rare colors that can be collected

including clear, burgundy, light green, straw and pink. The clear and light

green specimens are perhaps the most difficult colors to locate.

Let me

interrupt this discussion to make the point that there are a number of WGM

insulators that are suspect as to their color authenticity. In the 1970s, there

were several people in Colorado who experimented with heating purple WGM tolls

to high temperatures to come up with exotic colors. A large number of the

burgundy colored pieces in existence came about in this manner. Some of the pale

green insulators rarely found in the pony and toll shapes have also been

documented to be created through heating alterations. This is not to say

categorically that all burgundy and green WGMs are altered, but I certainly

regard every one that I encounter with suspicion!

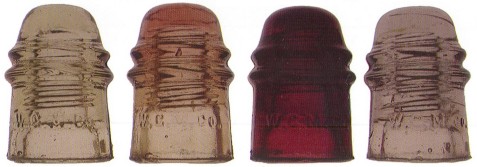

Next, let's consider the CD

121 tolls. These were the "workhorse" of the insulator world during

the early 1900s and were used for all the inner-mountain west long-line phone

circuits and phone communications for the burgeoning western mining industry.

The vast majority of the CD 121s are to be found in purple glass. In fact,

they are in hot demand by today's collector because they come in such a great

range of purple colors and are relatively inexpensive. I've shown here the range

of purples for the tolls. The darkest are known as "black purple" and

are almost impossible to see through without using a very bright light source.

These black purple pieces are actually just very dense royal purple glass. To my

eye, the medium and light shades of purple are more attractive, but "to

each his own"! A second photo shows some of the more exotic shades that the

tolls may be found in. In fact, the tolls come in more colors than any of the

other WGM CDs. Here we see the range from greenish straw, through peach and

burgundy, to silver. Other colors to be found include salmon, ginger ale, pale

green, golden straw, and pink. Many of the exotic light colored examples (and

this applies to all the other WGM CDs as well) have been found mounted in

attics, under eves of buildings, or covered with paint on the outsides of

various buildings. In such cases, the UV activation of the Manganese-induced

purpling has been prevented.

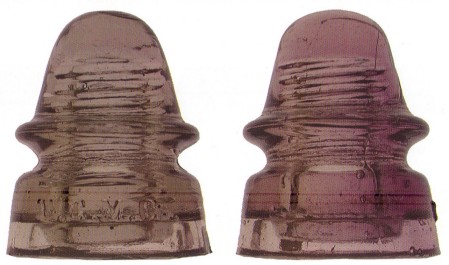

Next in the order of CD numbers, we have the CD 134

signal insulator. Again, note that this shape is the least common of all the WGM

styles.

Hard to find CD 106 Colors:

clear, burgundy, light green, straw, pink.

CD 121 Range of Purples: Black purple,

medium dark purple, light purple.

CD 121 Unusual Colors: Greenish straw,

light burgundy/peach two-tone,

burgundy, silver.

Range of purple coloring in CD 134 signals.

CD 134 in light straw, CD 121 with "hairlip", CD 134

"leaner".

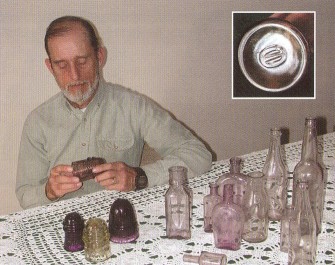

Western Glass Manufacturing specialist,

Tom Katonak, with WGM bottles and

insulators.

(Insert Photo)

"Belt -buckle" logo on a WGM whisky miniature.

Unusual CD 145s: Silver with amber swirls, dark purple with

cooling lehr

"kiss" on the right skirt, two-tone purple/straw.

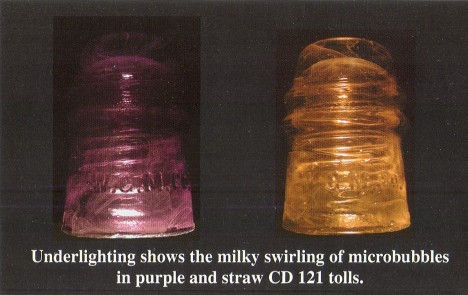

CD 145 medium purple narrow-dome style, rare greenish-gray and

an underlit

purple with milky swirling of microbubbles.

CD 162 Range of purples: Dark, medium and light purple.

Purple, straw and peach CD 162 signals.

Gray and two-tone examples of CD 162 signals.

When I first started specializing in WGM insulators, it took me nearly two

years to obtain a 134, and it was pretty badly damaged. The color range on these

tends more to the medium purple shade with light purple and deep purple being

more unusual. In a separate picture, I show the very rare light straw 134. I

have heard collectors talk about this unusual color for many years, but this is

the only specimen of this sort that I have ever personally seen.

The CD 145

comes next in the numerical lineup. The 145 shape was commonly used as the

railway telegraph insulator throughout the Rocky Mountain west. There are two

"sub-styles" of this shape: The classic chunky variant, and a

"slimmed down" version close to the shape of a postal style beehive

(see accompanying photo). By far, the chunky style is more common. Again, we

find royal purple to be a common color for this shape, but all shades of purple

are to be found including black purple on one end of the spectrum and light

lilac on the other. Very occasionally, the WGM beehives are found in silver or

straw, again the result of being used inside buildings or having had a coat of

paint applied so they were not subjected to the color-altering UV radiation.

While amber streaking is most unusual in WGM insulators, on the rare occasion

that you do find it in the WGM glass, the odds are that it will occur in a CD

145.

Finally, we come to the highest numbered WGM CD, the 162. The CD 162 was

used for signaling purposes on the Denver and Rio Grande Railroad, and also for

light power applications in many of the western towns. As it turns out, the

bases of the WGM CD 162s are relatively fragile; a large fraction of specimens

have considerable base damage. In fact, to find a WGM signal in so-called

"mint" condition is most unusual!

Again, most of the CD 162s are to be

found in various shades of purple. Probably the most common shade is close to

medium purple, but royal purple shades are available as are the very pale purple

shades. Interestingly, two-tone effects are perhaps most pronounced in this CD.

Beautiful combinations of straw and light rosy purple exist and are in high

demand. Light non-purple specimens occur occasionally like in the other WGM CDs,

although I have yet to find a pale green example. The accompanying photographs

show the range of purpling, straw and peach examples, and the gray and two-tone

specimens.

No discussion of the WGM glass insulators would be complete without

mentioning "misfits". By "misfits", I'm referring to

insulators that are misshapen, or contain bubbles, swirls of other colored

glass, or steam. Compared to the glass of the Western Flint Glass Company

production, which was known for its crudity, bubbles, swirls, gunk, etc., the

WGM operation produced pristine glass. You find very few bubbly pieces,

especially pieces with large bubbles, and only rarely pieces with steam or steamy swirls. I've included here some pictures of a pair of tolls full

of steam, and also a steam-swirled beehive. Such pieces are most uncommon in

tolls, and rare in other CDs. Apparently, the WGM plant had very good quality

control so the examples shown here of the toll with the under-pour and the CD

134 that leans are essentially "freak occurrences". It is also very

unusual to find dramatic amber swirls in the WGM glass. Occasionally one might

find a "spot" of amber, or a thin amber wisp, but almost never a

well-swirled piece. Deformation as a result of colliding or touching in the

cooling lehr also falls in with the "misfits". What happens in this

case is that an insulator in the lehr bumps up against another piece, and the

two stick together because the cooling glass is still soft and sticky. When the

workman separates the insulators, a small chunk of glass is pulled off one of

the pieces. Again, you don't see this very often because the workmen were quite

careful to keep the hot insulators well separated as they placed them on the

cooling table. You can see a photo example of the "lehr kiss" on the

right side of the skirt on a CD 145 in this article.

While quality control was

relatively good for an insulator manufacturer, certain aspects of quality

diminished as WGM ran into the lean years. I haven't done enough research to

determine how many different molds were used for each of the styles, but from

studying the glass, it is clear that the molds were used well beyond their

useful life. Late production insulators, particularly the tolls, show obvious

signs of mold damage due to heat. In several cases, the mold wear has been

repaired and you can see the imprint of the repair on the insulator itself.

Symptoms of spent molds include extrusion spurs along the mold lines and

"mushy" embossings.

The Bottles:

The Western Glass Manufacturing Company's major product was

glass bottles, and they supplied a vast number of bottles to the area's

commercial industries. Bottles of every shape and description were made during

the first decade of the 1900s. Many of the large food processors of the west

depended on WGM to supply them with bottles for the canning of foodstuffs. WGM

probably made more soda and beer bottles than anything else, but patent medicine

bottles and various food containers, for example pickle bottles, were in wide

distribution. The Kuner Company, a large Denver food processing and distribution

outfit, bought thousands of clear glass bottles to package their wares in. Many

of these bottles were embossed "KUNER" in large stick letters. A few

of the beer bottles were made of amber glass, much the same color as modern beer

bottles, but on the whole, WGM bottles were made of Manganese dioxide-laced

clear glass. These clear bottles eventually turned various shades of purple of

course, just like the insulators, but there are many more instances of finding non-purple glass as compared to finding clear insulators. One assumes

most bottles, once used, ended in landfills where they were not irradiated by

the sun. Many bottle dealers and collectors take the clear glass bottles and

place them in "purpling boxes" for a month or so to bring out the

purple colors. Strangely enough, there are no known examples of WGM insulators

occurring in light aqua, blue aqua and amber although these colors do occur in

the WGM bottles. This may indicate that there were actually two entirely

different process operations at the plant and that even the glass tanks were

separate. The trademark oval with a horizontal bar across the long axis

(nicknamed "the belt buckle") was usually embossed on the bottom of

each bottle to represent the logo depicted in this article. In rare cases, the

embossing "W.G.M. Co." is actually embossed on the bases.

Conclusions:

So here we have the story about one of America's most prolific

producers of glass insulators and bottles in the early part of the 20th Century!

In essence, the economy of the Rocky Mountain States rested on the output of a

small glass company in Valverde Colorado. Insulator collectors from around the

world treasure the beautiful purple glass with the W.G.M. Co. embossing.

Acknowledgments:

I would like to thank Denver glass authority Mike Miller for

his extensive consultation and advice. I am also indebted to Carol McDougald for

making all the photographs in this article look like real WGM insulators!

|